| 2003 | Preparations for production of plastic head, steel plate and etc. |

|---|---|

| 2004 | Began manufacturing pads, steel plates and other related accessories. |

| 2005 | Plan and design of pad printers; prepare to produce. |

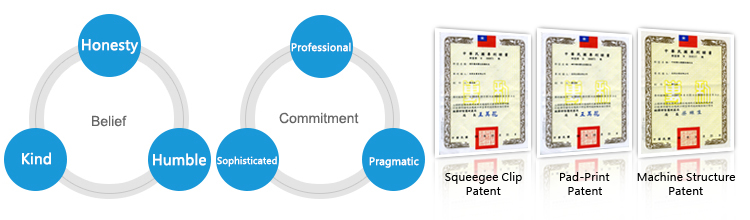

| 2006 | Started manufacturing pad printers, and filed numbers of patent applications. |

| 2007 | Began to manufacture all kinds of screen printers. |

| 2008 | Developments of small pad printers such as horizontal pad printer and a variety of other models. |

| 2009 | A: Developed six-color visual positioning pad printer successfully for Central Mint. Fast CCD judgement with servo motor and 20 precision rotary fixtures open a new era for the pad printing machines. B: All styles of the circular Pad/Screen printers. |

| 2010 | A: Launched new removable squeegee folder for constant users.It’s a lot quicker and more accurate to change the squeegee andadjust its position. B: The introduction of the high-voltage vacuum defoaming machineto manufacture the pads. |

| 2011 | A: Launched single color/2- color dervo pad printing machine. B: Launched 3-color auto pad printing machine + auto flip. C: Launched 4-color auto pad printing machine and 2-color auto pad printing machine. |

| 2012 | A: Launched auto flame ignition machine. B: Launched 2-color small round plate pad printing machine. C: Introduction of 2.5D measuring instrument for steel plate production. |